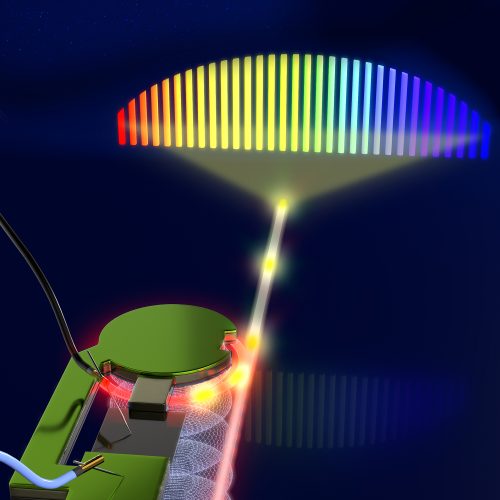

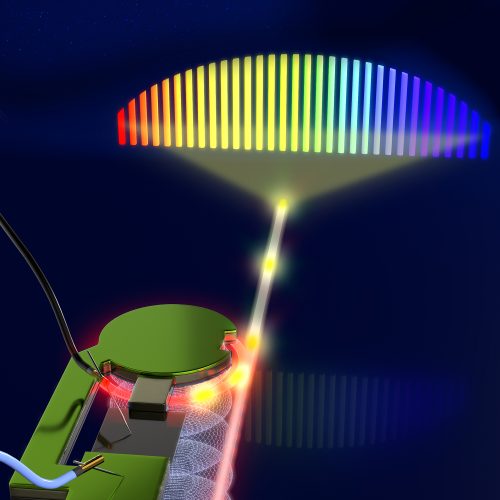

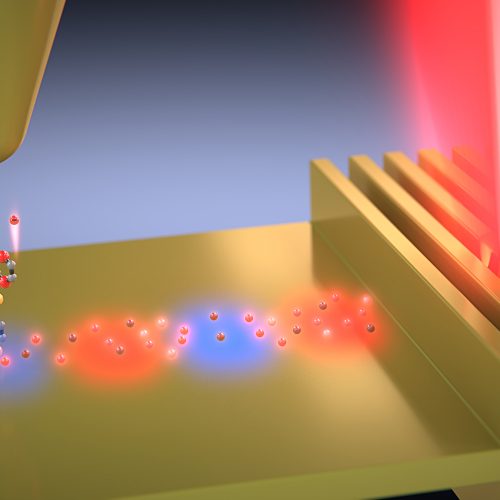

Light shaken and stirred to help autonomous vehicles better scan for nearby fast-moving objects

Light shaken and stirred to help autonomous vehicles better scan for nearby fast-moving objects

Purdue team gets $1 million to develop rapid sensor technology for cattle disease

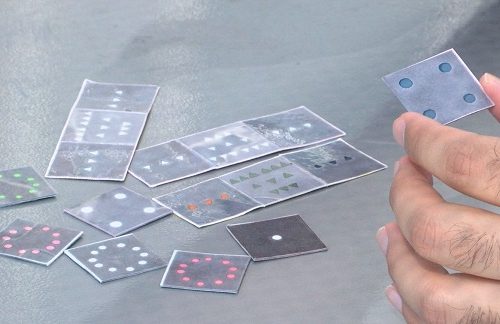

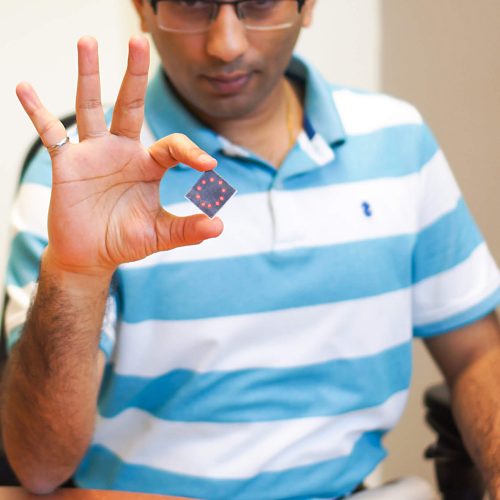

PURDUE UNIVERSITY STUDENTS CREATING AT-HOME COVID-19 TESTING DEVICE

Purdue teams up with 3M to produce PPE

Purdue University, Raytheon BBN Technologies, PortaScience, Cortex Design, and LaDuca partner on COVID-19 point-of-care test kit

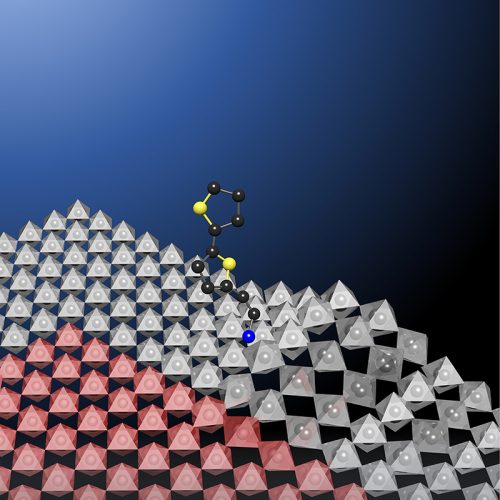

Discovery unlocks ‘hot’ electrons for more efficient energy use

Enabling highways and bridges to prevent their own damage

Purdue quantum research receives Department of Defense funding

Engineers make a promising material stable enough for use in solar cells

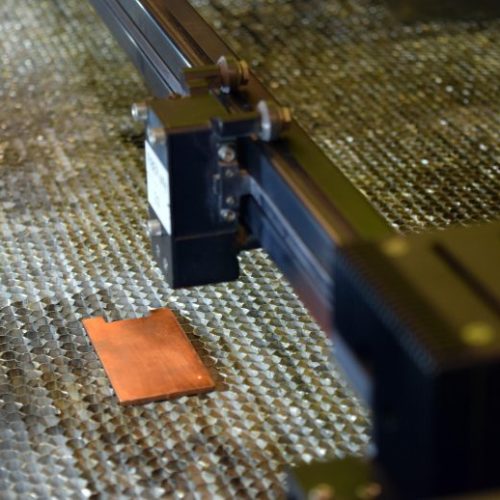

Now metal surfaces can be instant bacteria killers, thanks to new laser treatment technique